By A Mystery Man Writer

Download scientific diagram | Micrographs of the cross-section morphology of compression moulded samples after freeze-cracking and acid etching of the amorphous domains. The banded spherulite morphology of directly compression moulded samples from pellets is shown in (a) and (b). The morphology of the samples that had been extruded prior to compression moulding is shown for 10 s extrusion in (d) and for 6 min extrusion in (e). The fractured and etched cross-section of the manufacturer's LDPE is shown (c) from publication: Lamellae-controlled electrical properties of polyethylene – morphology, oxidation and effects of antioxidant on the DC conductivity | Destruction of the spherulite structure in low-density polyethylene (LDPE) is shown to result in a more insulating material at low temperatures, while the reverse effect is observed at high temperatures. On average, the change in morphology reduced the conductivity by a | Polyethylene, Conductivity and Antioxidants | ResearchGate, the professional network for scientists.

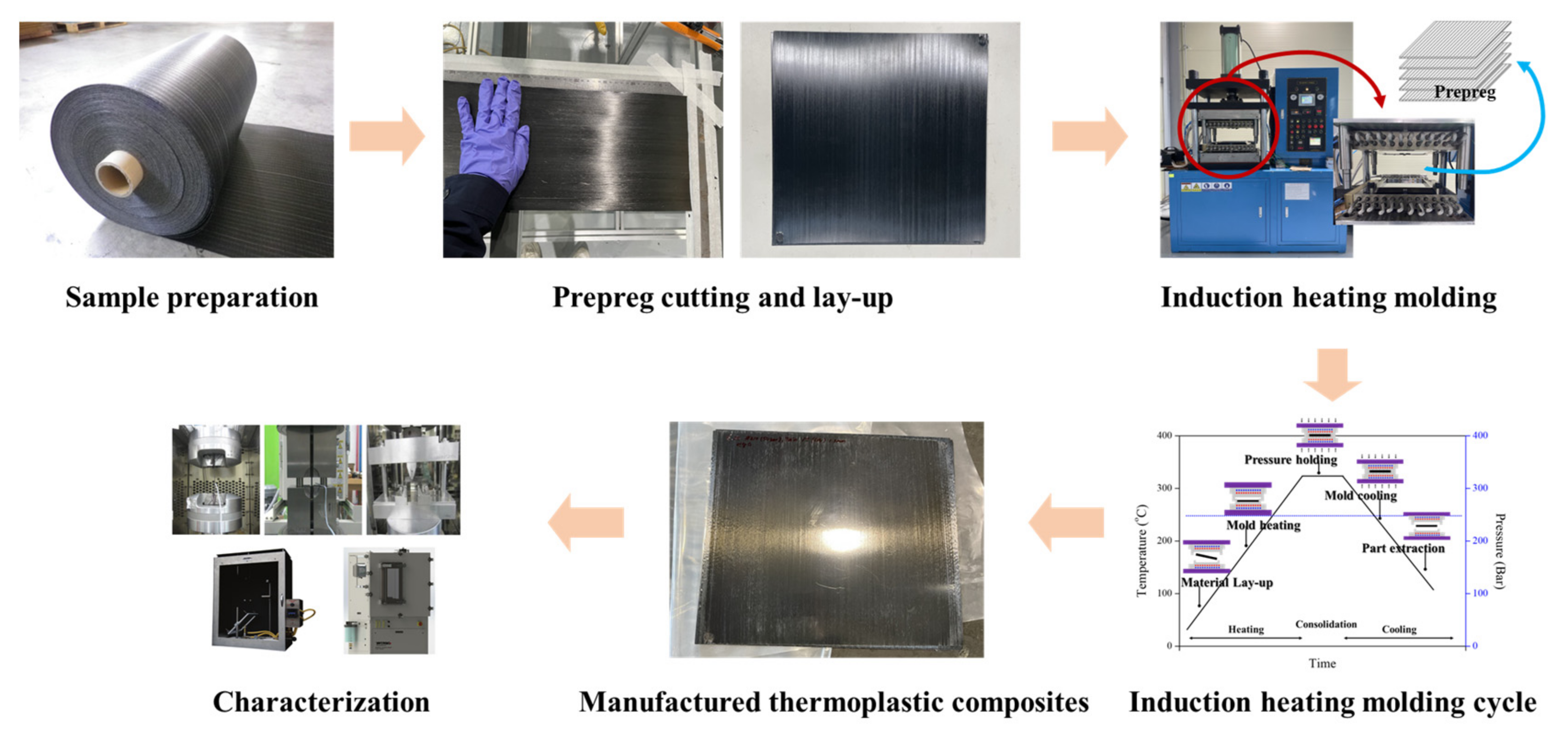

Effect of crystallinity and morphology on the mechanical properties of CF/PEKK composites manufactured under compression moulding and automated tape placement - ScienceDirect

Polymers, Free Full-Text

Fritjof NILSSON, Researcher, Docent (Associate Professor)

Microstructural and micromechanical property characterisation of CF/PEKK composites using nanoindentation - ScienceDirect

Sample preparation procedures used for preparing thin film-shaped

Thermal Resistance at the Polymer/Mold Interface in Injection Molding

Discrete element modeling of the compression molding of polymer–crystal composite particles - ScienceDirect

Effect of crystallinity and morphology on the mechanical properties of CF/PEKK composites manufactured under compression moulding and automated tape placement - ScienceDirect

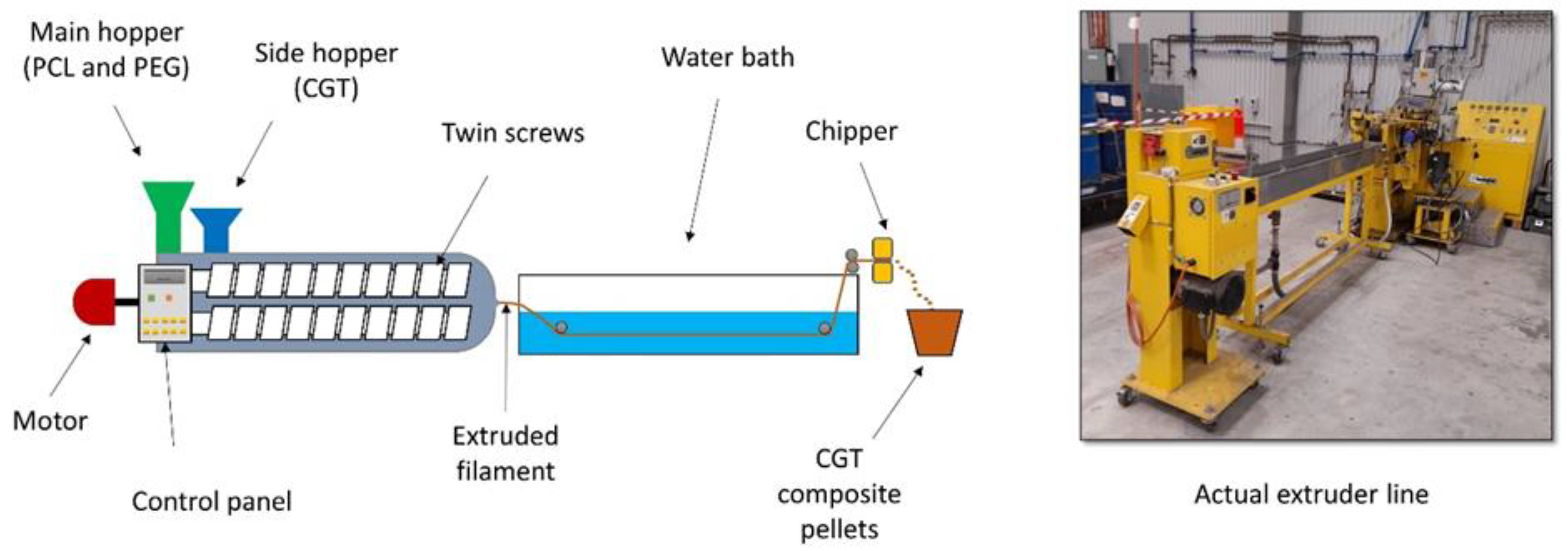

Opuntia Ficus Indica based green composites for NPK fertilizer controlled release produced by compression molding and fused deposition modeling - ScienceDirect

Polymers, Free Full-Text

Mass monitoring of two freshly cross-linked XLPE samples under

Xiangdong XU, Research specialist

Conductivity after 18 h polarization as a function of temperature

Experimental investigation of thermoset composite laminates manufactured with a novel sheet-winding compression-molding (SWCM) process - ScienceDirect

Hierarchical porous poly(L-lactic acid) fibrous vascular graft with controllable architectures and stable structure - ScienceDirect