Inconel 718 alloy has a wide range of applications in the aerospace sector because of its superior mechanical properties and its weldability. The machining of such higher strength materials with complex shapes is possible with wire electrical discharge machining. In the present research, an endeavor was made to enhance the machining process by utilizing zinc-diffused coating brass wire electrode and Taguchi-Data Envelopment Analysis-based Ranking (DEAR) methodology in the process while machining Inconel 718 alloy. Material removal rate, kerf width, and surface roughness were considered as the quality measures. The optimal arrangement of input factors in the Wire Electrical Discharge Machining (WEDM) process were found as 140 µs (Ton), 50 µs (Toff), 60 V (SV), and 5 kg (WT) among the elected factors with the error accuracy of 1.1%. The pulse-off time has the most significance on formulating the quality measures owing to its importance on deionization in the process.

PDF) Studies on Chromium-free Conversion coatings on Aluminum

RETRACTED ARTICLE: Solar energy optimization in solar-HVAC using

The Use of Engineered Silica to Enhance Coatings — American

Papkot™ - Replace plastic packaging with paper

Coatings, Free Full-Text

2-(3,4-Epoxy) ethyltriethoxysilane-modified waterborne acrylic

Catamount Coatings Premium Urethane 221 Clear Coat 7.5 Liter Kit

The ECP's Guide To Selling Anti-Reflective Coatings

Coatings, Free Full-Text, surf surf 1.101

Coatings, Free Full-Text

Figure S6. The averaged CoF for ML (Ni) , ML (Cu) and GnP-free ML

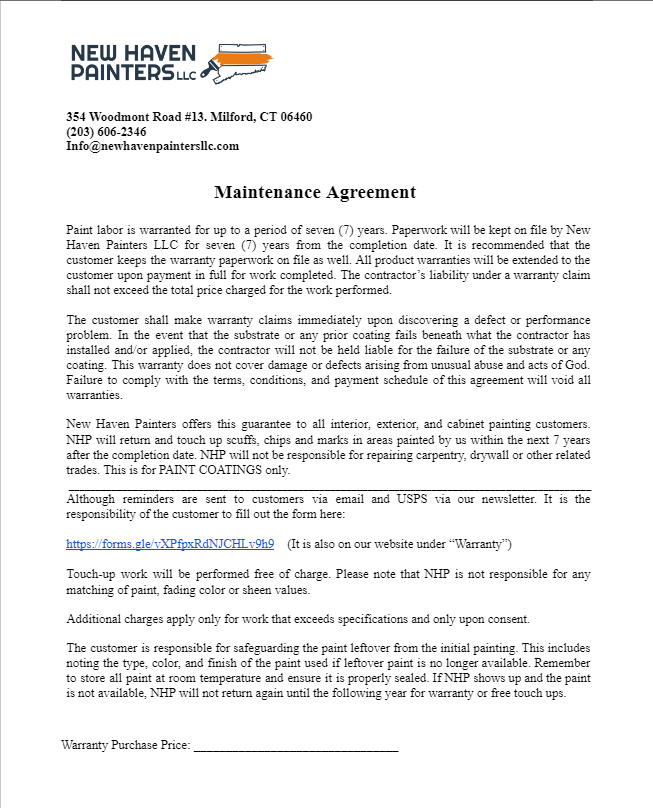

Painter Warranty, New Haven Painters LLC